PERFORMANCE OVERVIEW

The micro-lubricating oil for aluminum profiles is specially developed to address the problems existing in the rapid processing of soft metal alloys such as aluminum and copper. It is formulated with a variety of high-quality additives, free of sulfur, phosphorus and chlorine, thus being safe, reliable, environmentally friendly and harmless. It features high cost performance, smooth cut surfaces without burrs, low consumption, improved processing accuracy, and no smoke generation. Its quality can replace that of imported products from the United States, Japan and Germany.

PRODUCT APPLICABILITY

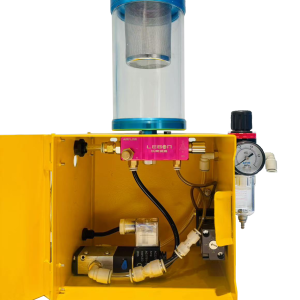

It is widely used in precision sawing of aluminum profiles, cutting with ripping saws, and quasi-dry micro-lubrication sawing processing of aluminum products. It completely volatilizes at high temperatures without any residue. The cut edges of aluminum materials are smooth, free of burrs. It is a truly stain-free and environmentally friendly oil. It needs to be used in conjunction with an automatic spray system device. It can solve problems such as the appearance of yellow spots in the aging furnace, unsmooth cut edges, burrs on the cut edges, smoke generation, aluminum adhesion, and rapid saw blade wear, thereby improving work efficiency and reducing the defect rate.

PRODUCT BENEFITS

The consumption is extremely low. Compared with traditional cutting fluids, it significantly reduces the production cost. It has excellent anti-wear and lubricating properties. The product penetrates quickly, leaving the cut edges bright and smooth. The special synthetic materials can prevent the appearance of “yellow spots” on aluminum materials in the aging furnace. It generates no smoke, effectively improving the workshop environment and being beneficial to the physical and mental health of the operators. It is an environmentally friendly product, odorless and will not damage the paint on equipment or rubber and plastic parts.